New Energy Vehicles (NEVs) represent the future of transportation. A crucial yet often overlooked component in these vehicles is the connector terminals. But why is material selection vital for these terminals, and what makes it so significant?

The material selection for connector terminals in New Energy Vehicles is essential due to the need for stable contact resistance, good mechanical strength and durability, lighter weight, easy processing into smaller sizes, and a certain degree of elasticity.

To grasp the full importance and nuances of this material selection, let’s delve deeper into each of these criteria.

The Role of Connector Terminals in NEVs

In the world of New Energy Vehicles (NEVs), every component plays a pivotal role in ensuring optimal performance, safety, and efficiency. Among these components, connector terminals stand out as silent workhorses, facilitating seamless energy transfer and communication within the vehicle. Let’s delve deeper into their significance.

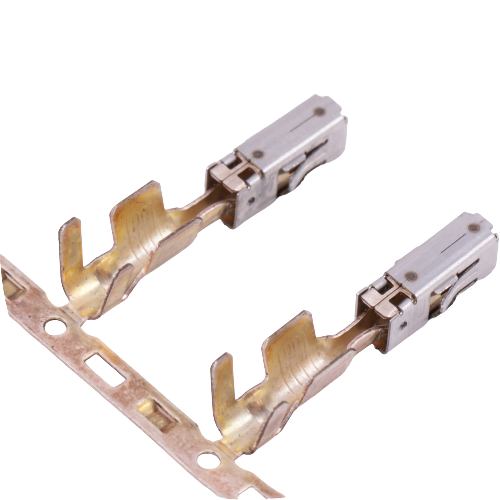

Basics of Connector Terminals

Connector terminals are specialized connectors designed to ensure a stable and efficient connection between different parts of an electrical system. In NEVs, these terminals are crucial for transmitting power from the battery to the motor and other essential systems. Their reliability directly impacts the vehicle’s performance, making their design and material selection of paramount importance.

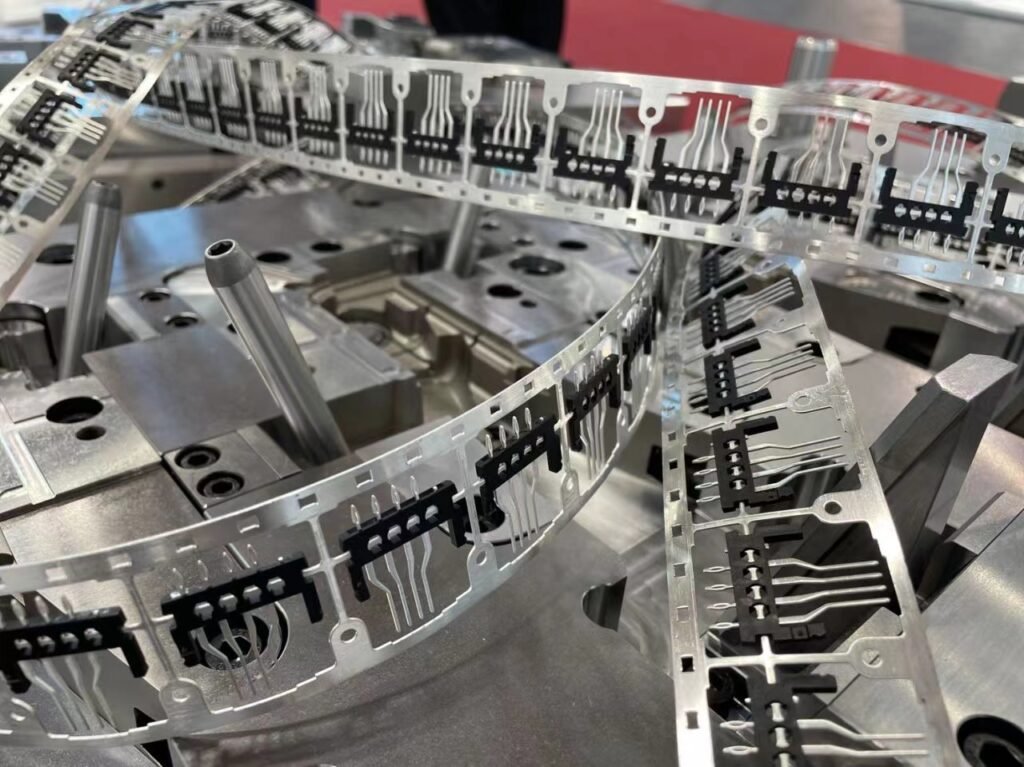

Evolution of Terminals in NEVs

As NEVs have evolved, so have their requirements for energy efficiency, miniaturization, and data transmission speeds. Connector terminals have had to adapt to these changing needs. From the early days of basic connectors to today’s advanced terminals capable of handling high currents and fast data rates, the journey of connector terminals mirrors the rapid advancements in NEV technology.

Structure and Functions of Terminals

At their core, connector terminals are designed to ensure a stable electrical connection. Structurally, they consist of a metal contact, an insulator, and often a locking mechanism. Their primary function is to ensure efficient energy transfer, but they also play roles in data transmission, grounding, and shielding against electromagnetic interference. In NEVs, their role is even more critical, given the high currents and the need for rapid data communication between various vehicle systems.

Types of Crimp Terminals

Crimp terminals, a subset of connector terminals, are designed for creating secure connections by physically crimping or compressing the terminal onto a wire. In NEVs, various types of crimp terminals are used, each tailored for specific applications:

- Ring Terminals: Ideal for screw or stud type connections.

- Spade Terminals: Used for quick-disconnect applications.

- Bullet Terminals: Suitable for quick-connect and disconnect scenarios.

- Butt Splice Terminals: Used to join two wires together.

Each type offers unique advantages, and their selection depends on the specific requirements of the NEV system they’re integrated into.

Criteria for Material Selection

The choice of material for connector terminals in New Energy Vehicles (NEVs) is not arbitrary. It’s a decision influenced by a myriad of factors, each playing a crucial role in ensuring the vehicle’s optimal performance. Let’s explore these criteria in detail.

Stable Contact Resistance

Contact resistance refers to the resistance encountered at the interface between two conductive materials, such as a wire and a terminal. For NEVs, maintaining a stable and low contact resistance is vital. High or inconsistent contact resistance can lead to energy losses, overheating, and even system failures. The chosen material must ensure minimal resistance, ensuring efficient energy transfer and overall vehicle performance.

Mechanical Strength and Durability

Given the dynamic environment within NEVs, connector terminals must possess robust mechanical strength. They should be able to withstand vibrations, temperature fluctuations, and other stresses without deformation or failure. Durability is equally important; the material should resist wear and tear, ensuring the terminals remain functional throughout the vehicle’s lifespan.

Light Weight and Size Considerations

With the push towards more efficient and agile NEVs, every gram counts. Materials for connector terminals should be lightweight without compromising on their functional properties. Additionally, as NEVs evolve, there’s a growing demand for miniaturization. The chosen material should be easily processable into smaller, compact designs without losing its essential characteristics.

Elasticity

While rigidity is essential for a stable connection, a certain degree of elasticity is also crucial. Elasticity ensures that the terminal maintains a secure connection even under dynamic conditions, such as when the vehicle is in motion. It also aids in the easy installation and removal of connectors, ensuring they snap into place securely and can be detached without excessive force.

Coating of Common Wire Terminals

Coatings play a dual role in connector terminals. Firstly, they act as a protective layer, shielding the terminal from environmental factors like moisture, which can lead to corrosion. Secondly, certain coatings can enhance the terminal’s electrical properties, reducing contact resistance and improving conductivity. Common coatings include gold, silver, and tin, each offering unique advantages. The choice of coating can significantly influence the terminal’s performance and, by extension, the overall efficiency of the NEV.

The Importance of Material Selection

The choice of material for connector terminals in New Energy Vehicles (NEVs) goes beyond mere functionality. It has far-reaching implications that can influence the vehicle’s efficiency, safety, and long-term operational costs. Let’s delve into why material selection is so pivotal.

Enhancing Vehicle Efficiency

The efficiency of an NEV is a culmination of various factors, and the material of its connector terminals plays a significant role. A material that ensures stable contact resistance, for instance, ensures optimal energy transfer, reducing losses. This not only boosts the vehicle’s performance but also its energy efficiency, leading to longer battery life and extended driving ranges. In essence, the right material choice can elevate the overall efficiency and performance of an NEV, offering a superior driving experience.

Safety Considerations

Safety is paramount in any vehicle, and NEVs are no exception. The material of the connector terminals directly impacts the safety of the vehicle and its occupants. Materials that can withstand high temperatures without degradation prevent overheating, a common cause of electrical fires. Additionally, materials that resist corrosion ensure consistent performance, reducing the risk of electrical failures that could compromise safety systems. In essence, the right material choice acts as a safeguard, ensuring the vehicle operates safely under various conditions.

Longevity and Maintenance

Every vehicle owner desires components that last long and demand minimal maintenance, and connector terminals are no exception. The choice of material can influence the longevity of these terminals. Materials that resist wear and tear, corrosion, and other forms of degradation ensure that the terminals remain functional for extended periods. This not only reduces the frequency of replacements but also cuts down on maintenance costs. In the long run, the right material choice can lead to significant savings, both in terms of time and money.

Conclusion

In the intricate ecosystem of New Energy Vehicles (NEVs), connector terminals may seem like small cogs in a vast machine. However, as we’ve explored, their role is undeniably significant. The choice of material for these terminals isn’t a mere technical decision; it’s a choice that reverberates through the vehicle’s efficiency, safety, and long-term operational viability.

From ensuring optimal energy transfer to safeguarding the vehicle and its passengers, the material of connector terminals plays a pivotal role. It also dictates the longevity of these components, influencing maintenance schedules and costs. As NEVs continue to gain traction in the global transportation landscape, the emphasis on material selection for connector terminals will only grow.

In essence, as we steer towards a more sustainable and eco-friendly future, the importance of making informed material choices for connector terminals becomes paramount. It’s a testament to the intricate balance of engineering, safety, and sustainability that defines the future of transportation.