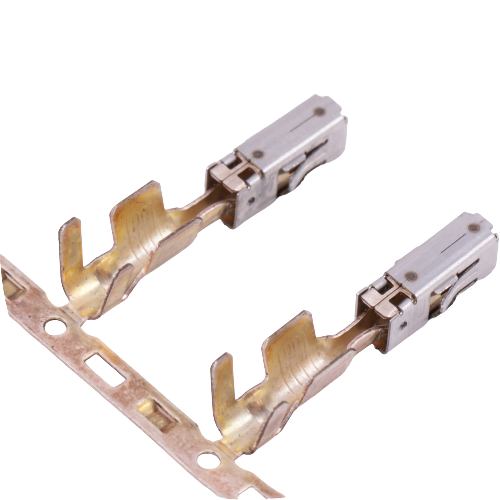

Delving into the world of New Energy Vehicles (NEVs), the spotlight often lands on the heart of electrical connections – the crimp terminals. Here, we unravel the principle of contact resistance, its significance, and how it shapes the efficiency and reliability of NEVs.

The additional resistance formed between the contact surfaces of the male terminal and the female terminal, post their connection, is termed as contact resistance in the realm of crimp terminals for new energy vehicles.

Journey with us as we explore the leading manufacturers, innovative materials, and designs, crimping techniques, and the overarching influence of contact resistance on the energy efficiency and longevity of NEVs.

Who are the leading manufacturers of crimp terminals optimized for new energy vehicles, and how do they address the contact resistance challenge?

In the domain of crimp terminals tailored for new energy vehicles (NEVs), several manufacturers stand out with distinct strategies to combat the contact resistance challenge:

- Molex: Molex is one of the recognized names in the industry, though the specific strategies they employ to tackle contact resistance in NEVs wasn’t detailed in the initial search. They likely utilize a mix of material science, innovative engineering, and stringent quality control measures to ensure reliable electrical connections in their crimp terminals.

- Phoenix Contact: Emphasizing the utilization of high-quality materials and innovative designs, Phoenix Contact aims to minimize contact resistance in crimp connections. Their crimp connections are crafted to create a gas-tight connection between the conductor and the contact, which is pivotal for reducing contact resistance.

- Micpro Precision: This manufacturer, based in China, ensures top-quality and customized automotive crimp terminals production, catering to a variety of industries including the NEV sector. Their precision stamping technique, along with advanced tooling design and fabrication, contributes to reducing contact resistance, ensuring reliable electrical connections1.

Moreover, notable manufacturers like TE Connectivity have been identified in the domain, although detailed strategies on how they address contact resistance weren’t found in the initial search. These companies, along with others in the sector, are likely employing a blend of material science, engineering innovations, and quality control measures to tackle the contact resistance challenge, ensuring their crimp terminals meet the demanding specifications of the NEV sector.

For a more exhaustive understanding, delving deeper into each manufacturer’s technical documentation and case studies, or engaging with them directly might unveil further insights into their specific approaches towards mitigating contact resistance in crimp terminals for new energy vehicles.

What materials and designs are most effective in reducing contact resistance in crimp terminals for new energy vehicles?

The materials and designs most effective in reducing contact resistance in crimp terminals for new energy vehicles largely hinge on the choice of metals and the engineering of the terminal interfaces. Here are some insights drawn from various resources:

- Materials:

- Tin Plating: One of the most commonly used terminal platings is tin plating. It’s a prevalent choice due to its ability to offer good electrical conductivity and resistance to corrosion2.

- High-Grade Copper: High-grade copper is often used as the base material for crimp terminals due to its excellent electrical conductivity. The copper body is usually tin-plated to enhance its performance3.

- Design Innovations:

- Contact Interface Geometry: The geometry of the contact interface plays a pivotal role in determining the contact resistance. The design aims to ensure that mechanical compression occurs over the full length of the conductor crimp, creating a common electrical path with low resistance45.

- Surface Roughness and Hardness: The surface roughness and hardness of the contact interface, along with the terminal’s normal force, determine the actual contact area. A smoother surface and adequate force help in achieving lower contact resistance by increasing the actual contact area of contact points6.

- Case Studies:

- While specific case studies showcasing the effectiveness of materials and design in reducing contact resistance weren’t found, the principles mentioned are well-acknowledged in the industry. Adhering to these principles, manufacturers optimize the contact interface geometry, select suitable materials, and control the surface conditions to mitigate contact resistance issues.

These materials and design strategies are tailored to ensure that crimp terminals in new energy vehicles provide reliable electrical connections with minimal resistance, which is crucial for the efficient operation of these vehicles.

Why is Contact Resistance Such a Critical Consideration for New Energy Vehicle Crimp Terminals?

Contact resistance is a pivotal consideration in the realm of New Energy Vehicle (NEV) crimp terminals due to its direct impact on the performance, reliability, and efficiency of the electrical connections within the vehicle. Let’s delve deeper into why it’s a focal point in NEV crimp terminal design and its real-world implications.

- Performance Enhancement:

- Lower contact resistance ensures a more efficient transmission of electrical signals or power between the mating terminals. This is crucial for the optimal performance of various electrical and electronic systems within the NEV.

- Energy Efficiency:

- High contact resistance can lead to energy losses in the form of heat generation at the contact points. Reducing contact resistance minimizes these losses, thereby enhancing the overall energy efficiency of the vehicle, which is particularly crucial in electric and hybrid vehicles to maximize battery life and driving range.

- Longevity and Reliability:

- Over time, elevated contact resistance can contribute to terminal overheating, potentially leading to premature failure or even damage to the adjacent components. Ensuring low contact resistance extends the longevity and reliability of the crimp terminals and the electrical systems they connect.

- Safety Considerations:

- Safety is paramount in NEVs, and high contact resistance could elevate the risk of overheating and potentially fire hazards. Ensuring low contact resistance through proper material and design choices is thus a critical safety measure.

- Cost Efficiency:

- Lower contact resistance can also contribute to cost efficiency. By reducing energy losses and enhancing system reliability, maintenance and energy costs are potentially lowered over the vehicle’s lifespan.

- Regulatory Compliance:

- Many regions have stringent regulatory standards regarding the energy efficiency and safety of NEVs. Adhering to low contact resistance standards is often a part of meeting these regulatory requirements, making it a critical consideration for manufacturers.

- Consumer Satisfaction:

- The practical implications of low contact resistance such as better energy efficiency, longer battery life, and enhanced system reliability are likely to enhance consumer satisfaction and trust in NEV technology.

The above elucidated points underline why meticulous attention to contact resistance is indispensable in the design and manufacture of crimp terminals for new energy vehicles. Through the prism of real-world implications, it’s clear that contact resistance is not just a technical specification, but a linchpin for the overarching goals of safety, efficiency, and reliability in the burgeoning field of NEVs.

How do different crimping techniques and tools influence the contact resistance of terminals in new energy vehicles?

Various crimping techniques can significantly impact the contact resistance of terminals in new energy vehicles (NEVs). Here are some factors and methods involved:

- Crimping Techniques:

- The crimping process needs to be precise to ensure a good connection between the wire and the terminal. The proper tooling, correct terminals for the application, a well-prepared wire, and a trained operator are crucial for achieving quality terminations and avoiding poor connections7.

- Level of Crimping:

- The level of crimping on new-energy vehicle wire terminals affects resistivity, contact resistance, and insulation performance of high-voltage wiring harnesses. Poor crimping can cause various adverse consequences, emphasizing the importance of proper crimping techniques8.

- Material Factors:

- The terminal material, contact interface geometry, terminal forward force, terminal contact interface surface state, voltage, and current are all factors that influence contact resistance9.

- Surface Electroplating:

- Electroplating the surface of the terminal helps to mitigate oxidation and corrosion on the metal surface, enhancing conductivity and reducing contact resistance. Common electroplating materials include tin, gold, silver, nickel, or chromium10.

Different crimping techniques and tools can significantly influence the contact resistance, affecting the overall performance and efficiency of the electrical connections in new energy vehicles. By optimizing the crimping process and choosing suitable materials and designs, it’s possible to minimize contact resistance, ensuring reliable and efficient electrical connections crucial for the functioning and performance of NEVs.

What are the Potential Pitfalls or Challenges When Trying to Minimize Contact Resistance in Crimp Terminals?

Minimizing contact resistance in crimp terminals for New Energy Vehicles (NEVs) is a nuanced endeavor fraught with potential pitfalls and challenges. Here’s an exploration of some of these challenges and strategies to overcome them:

- Material Selection:

- Challenge: The selection of appropriate materials that offer low contact resistance while meeting other requirements such as mechanical strength and corrosion resistance can be challenging.

- Strategy: Employing materials like high-grade copper for the terminal body and using surface electroplating techniques with materials like tin or gold can help in reducing contact resistance while maintaining other desired properties.

- Design Optimization:

- Challenge: Designing the terminal and contact interfaces to ensure a good mechanical and electrical connection can be intricate, requiring a fine balance between various factors.

- Strategy: Utilizing computer-aided design (CAD) tools and simulation software to optimize the geometry and surface characteristics of the contact interface can be beneficial.

- Manufacturing Consistency:

- Challenge: Maintaining consistent quality in the crimping process to ensure low contact resistance across all terminals can be difficult, especially at a large scale.

- Strategy: Implementing stringent quality control measures, employing automated crimping machines, and training operators on best practices can help maintain a high level of consistency.

- Testing and Validation:

- Challenge: Accurately measuring and validating the contact resistance of crimp terminals to ensure they meet the desired specifications can be technically challenging.

- Strategy: Employing advanced testing equipment and methodologies to measure contact resistance, and validating the results through rigorous quality assurance protocols.

- Cost Implications:

- Challenge: The cost implications of employing high-quality materials and advanced manufacturing techniques to minimize contact resistance can be significant.

- Strategy: Balancing the cost with the performance benefits through careful material selection, design optimization, and efficient manufacturing processes can help mitigate the cost implications.

- Regulatory Compliance:

- Challenge: Meeting the stringent regulatory standards related to contact resistance, especially in different regions, can be a challenge.

- Strategy: Staying updated on the regulatory requirements, and designing and manufacturing the crimp terminals to meet or exceed these standards can ensure compliance.

- Technological Advancements:

- Challenge: Keeping pace with the technological advancements in materials and manufacturing techniques to continually minimize contact resistance.

- Strategy: Engaging in continuous research and development, and collaborating with industry stakeholders to leverage the latest advancements in the field.

Tackling these challenges necessitates a holistic approach that spans material science, engineering design, manufacturing excellence, and rigorous testing and validation. Through collaborative efforts among manufacturers, suppliers, and regulatory bodies, the goal of minimizing contact resistance in crimp terminals for NEVs, while navigating the associated challenges, can be progressively achieved.

Why is the Principle of Contact Resistance Even More Crucial for New Energy Vehicles Compared to Traditional Vehicles?

The principle of contact resistance takes on heightened significance in New Energy Vehicles (NEVs) as compared to traditional internal combustion engine vehicles due to several compelling factors. Here’s a comparative analysis elucidating the amplified importance of contact resistance in NEVs:

- Energy Efficiency:

- NEVs: The energy efficiency of NEVs is directly influenced by contact resistance in crimp terminals as high resistance can lead to energy losses, which is detrimental to the battery life and overall vehicle range.

- Traditional Vehicles: While energy efficiency is important, the impact of contact resistance is less pronounced as the primary energy source is fuel combustion.

- Electrical Dependency:

- NEVs: NEVs heavily rely on electric circuits for propulsion and operation of various systems. Lower contact resistance ensures better electrical conductivity and system performance.

- Traditional Vehicles: Though they have electrical systems, the dependency on electrical circuits is less compared to NEVs, making contact resistance less critical.

- Battery Life:

- NEVs: Prolonging battery life is crucial in NEVs, and minimizing contact resistance helps in reducing energy losses, thereby extending battery life.

- Traditional Vehicles: Battery life is not as critical since the primary energy source is the fuel.

- Thermal Management:

- NEVs: High contact resistance can result in overheating at connection points, necessitating robust thermal management systems to prevent damage.

- Traditional Vehicles: Thermal management is primarily focused on engine cooling, with less concern about electrical connection overheating due to contact resistance.

- Safety Considerations:

- NEVs: With high-voltage systems and batteries, ensuring low contact resistance is a vital safety measure to prevent overheating and potential fire hazards.

- Traditional Vehicles: Safety concerns related to contact resistance are less pronounced.

- Regulatory Compliance:

- NEVs: Stricter regulatory standards on energy efficiency and safety in many regions necessitate low contact resistance in NEVs.

- Traditional Vehicles: The regulatory standards concerning contact resistance are less stringent.

- Consumer Expectations:

- NEVs: Consumers often have high expectations regarding the efficiency and performance of NEVs, which can be met by minimizing contact resistance.

- Traditional Vehicles: Consumer expectations around efficiency are often not as high, making contact resistance a lesser concern.

- Innovation and Technological Advancements:

- NEVs: The rapid innovation in NEV technology often centers around improving electrical efficiency, where minimizing contact resistance plays a pivotal role.

- Traditional Vehicles: Innovations may not be as focused on electrical efficiency and contact resistance reduction.

The juxtaposition of these factors underscores the paramountcy of contact resistance in the realm of NEVs. The overarching goal is to harness the potential of electric power efficiently and safely, and addressing contact resistance is a linchpin to achieving this objective in the transition towards cleaner and more sustainable automotive technologies.

How Does the Principle of Contact Resistance in Crimp Terminals Correlate with the Overall Energy Efficiency and Lifespan of New Energy Vehicles?

The principle of contact resistance in crimp terminals holds a pronounced correlation with both the energy efficiency and the lifespan of New Energy Vehicles (NEVs). Here’s a delve into how these facets interlink:

Contact Resistance and Energy Efficiency

- Energy Transmission Efficiency:

- Lower contact resistance ensures a more seamless and efficient transmission of electrical energy from the battery to various vehicular systems. Any resistance encountered en route translates to energy losses, predominantly in the form of heat, diminishing the energy efficiency of the vehicle.

- Battery Performance and Range:

- The cumulative effect of contact resistance across numerous connections can significantly impact the overall battery performance and, by extension, the driving range of the NEV. Lower contact resistance allows for better utilization of the battery’s charge, extending the vehicle’s range per charge.

- Heat Dissipation Needs:

- Higher contact resistance leads to increased heat generation at the crimp terminals, necessitating more robust and often complex thermal management systems to dissipate this heat, which could otherwise negatively impact the efficiency and functionality of nearby components and systems.

Implications on NEV Lifespan

- Terminal and Connector Longevity:

- Lower contact resistance aids in averting overheating and undue wear and tear on the terminals and connectors, thereby enhancing their longevity and, by extension, reducing the maintenance and replacement needs over the vehicle’s lifespan.

- Battery Lifespan:

- By fostering better energy efficiency and reducing the load on the thermal management systems, lower contact resistance indirectly contributes to prolonging the battery’s lifespan as well. Less energy wasted as heat translates to less thermal stress on the battery, promoting a longer operational life.

- System Reliability:

- A network of reliable connections with low contact resistance contributes to the overall reliability of the electrical and electronic systems in the NEV. This reliability extends the lifespan of the vehicle by reducing the likelihood of electrical failures and the associated repair and maintenance requirements.

- Safety and Durability:

- Ensuring low contact resistance is also a safety imperative, as it helps mitigate risks associated with overheating and potential fire hazards, thereby enhancing the overall durability and safety profile of the NEV.

- Cost Efficiency over Lifespan:

- Lower maintenance needs, extended battery life, and improved energy efficiency contribute to a more cost-effective ownership experience over the lifespan of the NEV.

In summation, the principle of contact resistance in crimp terminals is a crucial determinant of both the energy efficiency and lifespan of NEVs. By minimizing contact resistance, manufacturers and designers are setting the stage for more efficient, reliable, and long-lasting new energy vehicles, aligning with the broader objectives of sustainability and cost-effectiveness in modern mobility solutions.

Conclusion

The discourse on contact resistance in crimp terminals unveils a critical facet of NEV technology. As we steer towards a greener future, understanding and addressing the challenge of contact resistance in crimp terminals emerges as a pivotal stride. Through the lens of leading manufacturers, innovative designs, and crimping methodologies, the narrative sheds light on the path towards optimizing the performance and reliability of new energy vehicles.