Metal stamping is a precise and versatile manufacturing process that plays a crucial role in various industries. The success of metal stamping heavily relies on maintaining accurate tolerances to ensure the production of high-quality components. In this article, we will delve into the importance of metal stamping tolerances and explore techniques that can help achieve precision and tight tolerances.

1. Understanding Metal Stamping Tolerances

Metal stamping tolerances refer to the allowable deviation in dimensions and specifications during the stamping process. These tolerances determine the accuracy and quality of the final metal components. Maintaining tight tolerances is vital to meet design requirements, functionality, and compatibility with other parts.

2. Importance of Precise Tolerances

Metal components with precise tolerances ensure proper fit and functionality within the assembly. Tight tolerances contribute to the seamless operation of the final product, reducing the risk of malfunctions or failures. Furthermore, precise tolerances enable optimal performance, durability, and safety of metal components in various applications.

3. Techniques to Achieve Precision

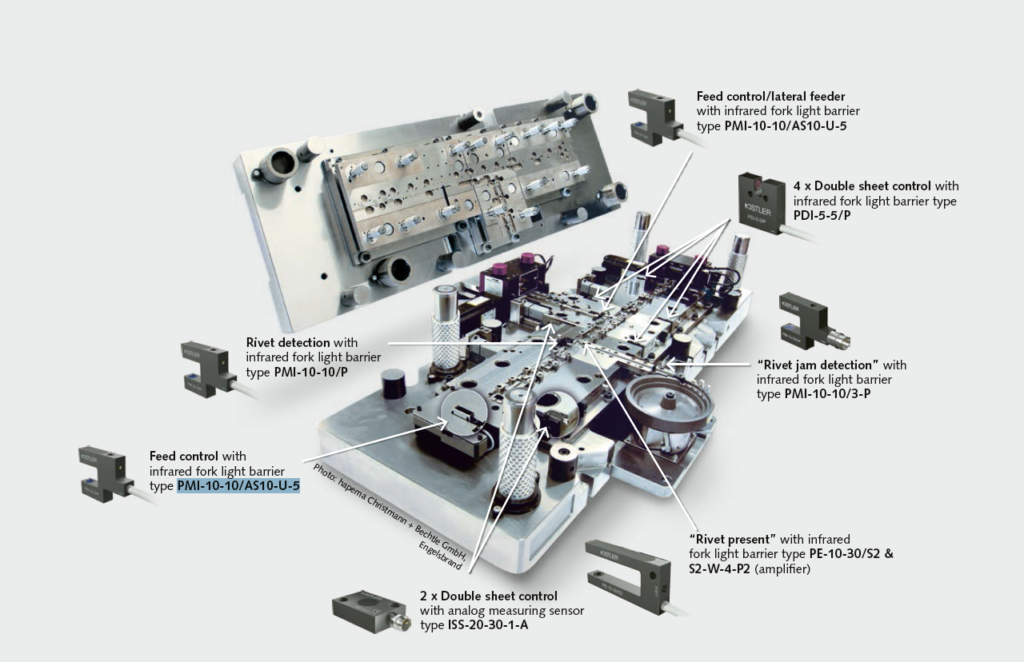

Advanced Tooling and Equipment

Investing in high-quality tooling and equipment is paramount for achieving accurate tolerances in metal stamping. Precision dies, presses, and measuring instruments are essential components of the stamping process. Modern technologies like computer numerical control (CNC) machining and inspection systems enhance precision, repeatability, and efficiency.

Material Selection and Control

Choosing suitable materials and maintaining proper material control throughout the manufacturing process are crucial for achieving precise tolerances. Material characteristics, including hardness, ductility, and thermal expansion, directly influence dimensional stability. Proper material selection and control ensure consistency and reliability in the stamped metal components.

Process Optimization

Implementing rigorous process optimization techniques, such as statistical process control (SPC), can help monitor and control variations during metal stamping. SPC enables real-time adjustments, minimizing deviations and enhancing consistency. Additionally, techniques like Six Sigma and lean manufacturing can improve efficiency, reduce waste, and further enhance precision in metal stamping.

Quality Assurance Measures

Robust quality assurance practices play a vital role in achieving and maintaining precise tolerances in metal stamping. Thorough inspections, measurements, and testing ensure adherence to tolerances and help identify any deviations or defects. Non-destructive testing methods, such as laser scanning and coordinate measuring machines (CMM), verify dimensional accuracy and ensure the quality of the stamped components.

4. Overcoming Challenges

Metal stamping comes with its own set of challenges that can impact tolerances. Understanding and addressing these challenges are essential to achieving precision.

Springback and Elasticity

Metal stamping involves elastic deformation, leading to springback after the forming process. Springback refers to the tendency of the metal to return to its original shape after being stamped. This can cause deviations from the desired tolerances. To overcome this challenge, careful consideration of material properties and tooling adjustments is necessary. Techniques such as over-bending and utilizing specific tooling designs can compensate for springback and maintain precise tolerances.

Environmental Factors

Temperature variations, humidity, and other environmental factors can also impact metal stamping tolerances. These factors can cause thermal expansion or contraction of the metal, affecting its dimensions. To mitigate the effects of environmental factors, implementing controlled environments or incorporating compensating measures such as preheating or cooling the material can help maintain consistent and accurate tolerances.

Conclusion

Achieving precision in metal stamping tolerances is vital for the production of high-quality metal components. Maintaining tight tolerances ensures proper fit, functionality, and compatibility while enhancing the overall quality, reliability, and performance of the final product. By employing advanced techniques, optimizing processes, and implementing rigorous quality assurance measures, manufacturers can consistently achieve accurate tolerances and meet the demanding requirements of various industries.

Remember, precision in metal stamping tolerances is the key to success in delivering exceptional products that surpass customer expectations and drive industry advancements.