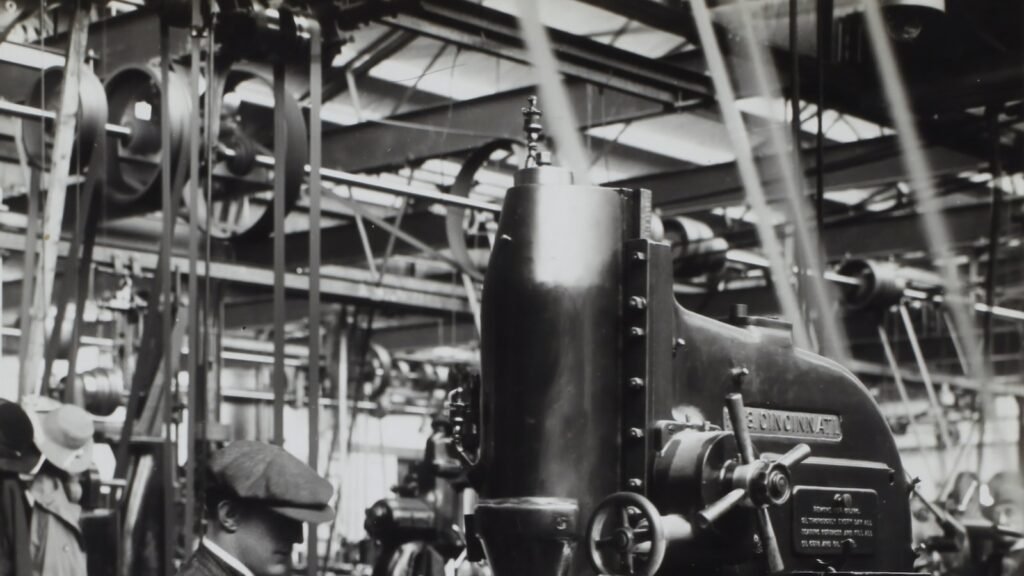

In the dynamic world of modern manufacturing, there is an exciting change taking place – a change that blends innovation with industry, technology with tradition. The rise of Industry 4.0 is tantamount to a renaissance in manufacturing, and its impact on industries such as stamping production is transformative. This article is an enlightening exploration of the many benefits of adopting Industry 4.0 practices in stamping manufacturing.

Pinnacle of Automation: A New Dawn of Operations

The advent of Industry 4.0 introduces an era where automation is elevated to an unprecedented pinnacle. Stamping manufacturers are now equipped to seamlessly integrate cutting-edge robotics and AI-driven systems into their production lines. For instance, stamping machines can autonomously adjust parameters to achieve impeccable precision, minimizing human intervention. This level of automation not only reduces errors but also boosts production speed, significantly impacting operational efficiency and product quality.

Precision Perfected: Elevating Product Excellence

Industry 4.0 empowers stamping manufacturers to redefine precision. With the integration of advanced sensors and real-time monitoring, deviations in product dimensions are detected instantly. This level of precision ensures that every product adheres to the strictest tolerances. For instance, automotive components created through stamping maintain consistent dimensions, directly enhancing their performance and longevity.

The Power of Data-Driven Insights

In the age of Industry 4.0, data is more than just information – it’s a game-changer. Stamping manufacturers harness the power of big data to make informed decisions. Real-time data streams from machines provide insights into performance trends, enabling predictive maintenance. For example, when a stamping machine’s wear is detected through data analysis, maintenance can be scheduled proactively, minimizing downtime and optimizing production.

Maximizing Efficiency and Resource Utilization

Resource utilization reaches an unprecedented zenith with Industry 4.0. Smart factories optimize energy consumption by dynamically adjusting power usage based on production demands. Moreover, material waste is minimized through precise material calculations enabled by data-driven algorithms. As a result, stamping manufacturers not only reduce their environmental footprint but also enhance cost-efficiency.

Real-time Monitoring and Proactive Maintenance

Real-time monitoring is the backbone of Industry 4.0. Stamping machines are equipped with sensors that continuously monitor factors like temperature, vibration, and performance metrics. Anomalies trigger immediate alerts, allowing for proactive maintenance. For instance, a deviation in vibration levels could indicate impending issues, enabling maintenance teams to intervene before a breakdown occurs.

Agile Manufacturing and Bespoke Solutions

Industry 4.0 ushers in the era of agile manufacturing. Stamping manufacturers can swiftly adapt their production lines to accommodate custom orders without disrupting efficiency. For example, a medical device company can modify stamping processes to create specialized components for unique surgical tools, catering to individual client needs with minimal lead time.

Synergy in Supply Chain Management

Supply chain management becomes a symphony of efficiency through Industry 4.0. Manufacturers share real-time data with suppliers, enabling just-in-time deliveries. For instance, an automotive stamping facility communicates production demands to material suppliers, ensuring raw materials arrive precisely when needed. This synchronization minimizes inventory costs and eliminates production delays.

Empowering the Workforce with Augmented Reality

Augmented Reality (AR) becomes a tool of empowerment in Industry 4.0. Stamping operators don AR glasses that overlay real-time data onto their field of vision. They receive step-by-step instructions, reducing the need for extensive training and enhancing productivity. For example, an operator assembling intricate stamping tools can follow AR-guided instructions, minimizing errors and speeding up production.

Sustainable Practices and Conservation

Industry 4.0 bridges manufacturing with sustainability. Smart factories optimize energy consumption and minimize waste. Stamping manufacturers can track energy usage patterns and implement energy-saving strategies. Additionally, data-driven material utilization ensures minimal waste production. These practices contribute to reduced environmental impact and sustainable manufacturing.

Navigating the Frontiers of Cybersecurity

The digital transformation of Industry 4.0 brings forth the paramount importance of cybersecurity. Stamping manufacturers implement robust cybersecurity measures to protect sensitive data from cyber threats. For example, data encryption, secure networks, and regular vulnerability assessments fortify the digital infrastructure, ensuring safe operations and safeguarding intellectual property.

Forging Ahead: Embracing the Future of Industry 4.0

The future is brimming with opportunities as Industry 4.0 continues to evolve. Stamping manufacturers embracing this revolution are positioned at the forefront of progress. As technologies advance and interconnectivity deepens, stamping production will redefine the boundaries of excellence, efficiency, and innovation.

Conclusion

Industry 4.0 transforms manufacturing into a realm of endless possibilities. By merging tradition with technology, this revolution elevates stamping production to unparalleled heights of excellence. The benefits of Industry 4.0 aren’t just theoretical – they are tangible improvements that amplify precision, efficiency, sustainability, and innovation. As the era of Industry 4.0 unfolds, the stamping industry is poised to rewrite its legacy and reshape the future of manufacturing.