Welcome to the world of metal stamping, where precision meets creativity and functionality. Metal stamping is a versatile and essential manufacturing process that has revolutionized multiple industries, from automotive to aerospace. In this guest post, we will delve into the captivating world of metal stamping, exploring its significance, applications, and the incredible precision it offers. So, buckle up and get ready to unlock the power of metal stamping!

Section 1: The Art of Metal Stamping

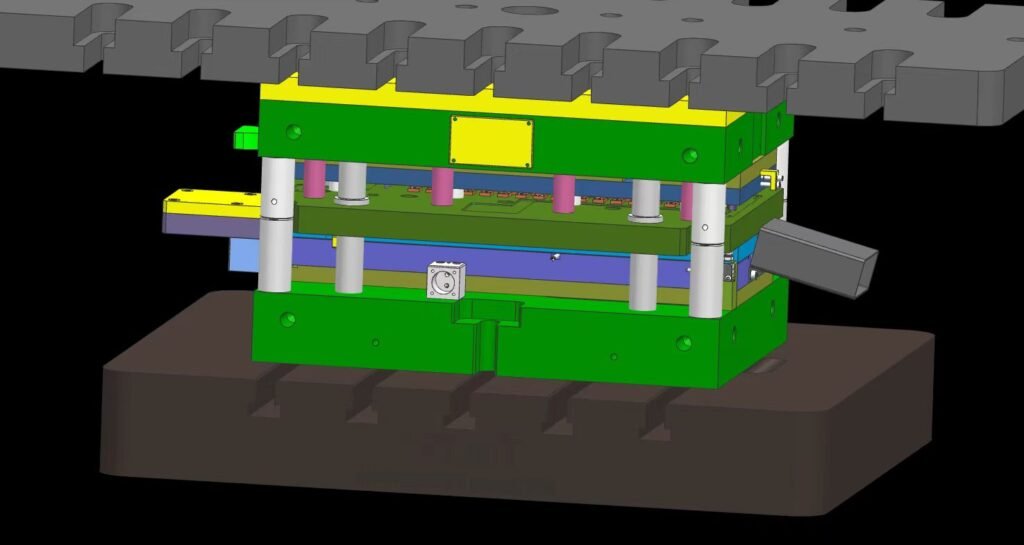

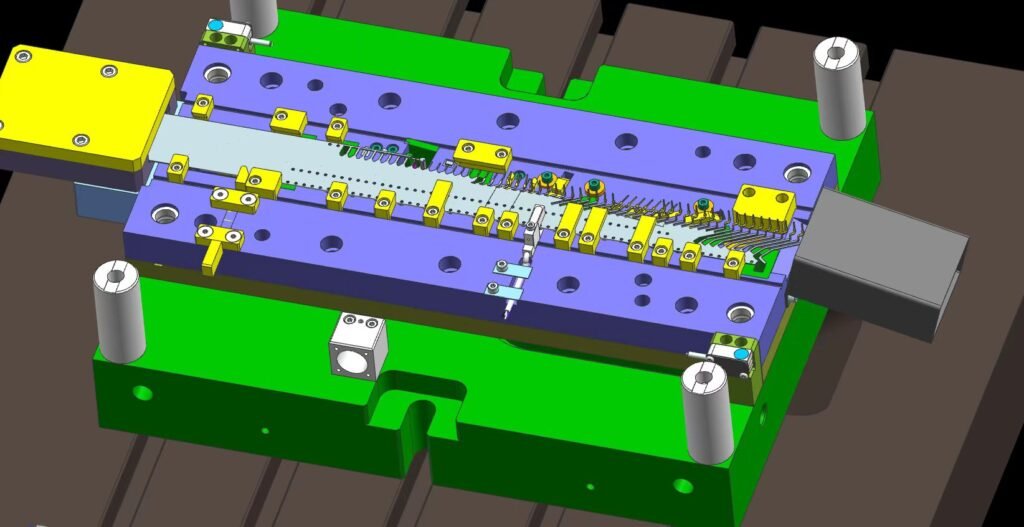

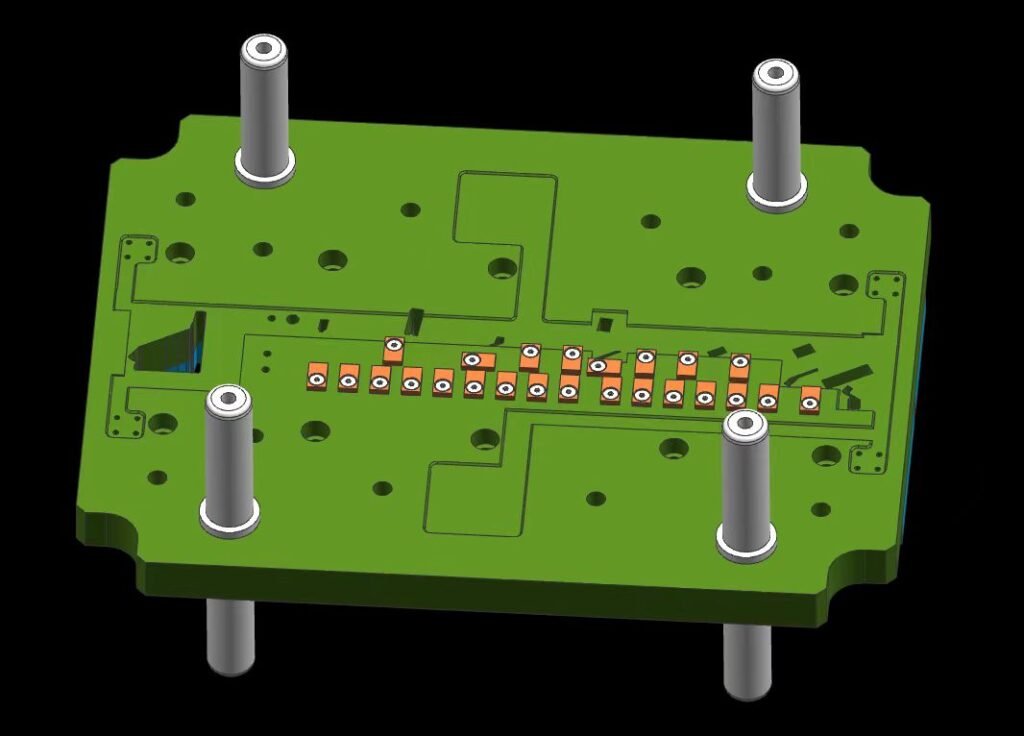

Metal stamping is more than just a manufacturing process; it’s an art form that combines engineering expertise, craftsmanship, and cutting-edge technology. At its core, metal stamping involves the transformation of flat metal sheets into desired shapes and forms using specialized tools and machines. By applying pressure, the metal is precisely shaped, cut, and formed into intricate designs or functional components.

Section 2: The Significance of Precision

Precision is the backbone of metal stamping. The ability to create intricate and accurate designs is what sets metal stamping apart. With the aid of computer-aided design (CAD) software, manufacturers can translate complex ideas into precise specifications. This level of precision ensures that every component produced through metal stamping fits seamlessly within the intended assembly, minimizing errors and improving overall product quality.

Section 3: Applications of Metal Stamping

Metal stamping finds its application in a wide range of industries. Let’s explore some key sectors that benefit from the versatility and efficiency of metal stamping:

- Automotive Industry: Metal stamping plays a crucial role in the production of automotive components such as body panels, brackets, and engine parts. Its ability to rapidly produce complex parts with high accuracy and repeatability makes it an invaluable process in the automotive manufacturing world.

- Electronics and Appliances: From computer components to household appliances, metal stamping ensures the production of durable and precise parts. Connectors, brackets, and heat sinks are just a few examples of items that are manufactured using metal stamping techniques.

- Aerospace and Defense: In the aerospace and defense sectors, precision and reliability are paramount. Metal stamping is widely used to fabricate critical components such as aircraft panels, missile parts, and defense system components. The high strength-to-weight ratio of stamped metal parts makes them ideal for these demanding applications.

- Medical and Healthcare: Metal stamping enables the production of intricate and precise medical devices and implants. From surgical instruments to prosthetic components, metal stamping ensures the highest level of accuracy and functionality, contributing to advancements in healthcare.

Section 4: The Advantages of Metal Stamping

Metal stamping offers several advantages that make it a preferred manufacturing process for many industries:

- Cost-Effective Production: Metal stamping allows for high-volume production at a lower cost per unit. The ability to rapidly produce identical components reduces labor costs and increases overall efficiency.

- Versatility and Design Freedom: Metal stamping offers great design flexibility, allowing manufacturers to create custom shapes and features. Complex designs can be achieved with ease, enabling product innovation and differentiation.

- Durability and Strength: Stamped metal parts exhibit excellent strength and durability due to the uniformity of the metal structure. These parts can withstand harsh environments and heavy loads, ensuring long-lasting performance.

- Efficiency and Speed: Metal stamping processes, such as progressive stamping, enable the rapid production of components with minimal material waste. This efficiency allows manufacturers to meet tight production deadlines and market demands.

Section 5: The Future of Metal Stamping

Looking ahead, the future of metal stamping appears promising. As industries continue to demand lighter, stronger, and more intricate components, metal stamping will play a vital role in meeting these requirements. The integration of automation and robotics into metal stamping processes will further enhance productivity, reduce costs, and improve safety. Furthermore, the rising adoption of sustainable manufacturing practices will drive the development of eco-friendly stamping techniques and materials.

Conclusion

Metal stamping has proven to be a game-changer in the manufacturing industry, offering unparalleled precision, cost efficiency, and versatility. Its applications span across various sectors, and with ongoing technological advancements, metal stamping is poised to continue resh